Table Saw Buying Guide for New & Intermediate Level Users

Woodworkers are well aware that they’re gonna’ need serious cutting tools at some point in their morbid careers. I am talking about specific power tools which are high up the league, such as; chainsaws, jig saws and table saws. Speaking of the latter kind, this detailed table saw buying guide is all about buying your table saw the way it’s meant to be - that means getting down to the brass tacks and discussing different aspects of what would be an ideal table saw.

This article was also written in an attempt to help you buy something decent in terms of longevity, and performance that meets your requirements. I am sure that there are a lot of experts out there who would beg to differ. In fact, if I were being honest right now, I’d say that this article may not be a “picture perfect” representation of an ideal table saw.

Table saws are not cheap; they are expensive and they cost a fortune under certain conditions. God forbid, if you bought a table saw on a whim, and ended up with something completely opposite of your project requirements, then that’d be a shame – and a waste of money of course. More so, it is not easy to file for refunds as come retailers refuse to cooperate. In this context, you need some sort of guidance before you end up buying a table saw for the first time.

Using a Table Saw Directly Affects The End Output:

Consider a table saw blade as a hungry little hippo, which pulls everything in its mouth. Since the blade is fixed in a specific position, you only need to slide the wood slabs a little. The rest is taken care of automatically. The blade is also made in such a way that its rotation causes the material to slide towards it.

However, that’s just about the extent of a newbie’s knowledge about using table saws. This is exactly why a lot of people make mistakes which can cost dearly in terms of unforeseen injuries, and maintenance factors. While the following part of this post is not a typical ‘how to use a table saw’ sort, I wanted to share a few tips that will refine your experience.

What are the Different Types of Table Saws Available These Days?

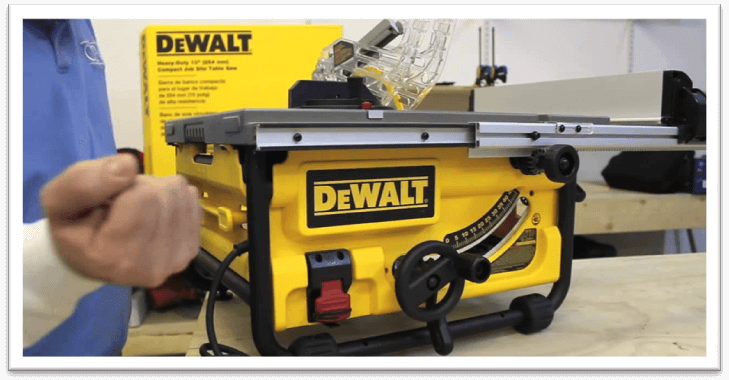

There are two main categories of table saws to choose from. If portability is your main concern, then you should go for bench top table saws such as Dewalt DW745. They are small and usually come within the 10” blade size variation.

For the record, I have already reviewed a bunch of bench top table saws at PowerTool Buzz; you can surf around in the table saws reviews section to read a few detailed articles about those products. Bench top table saws such as Craftsman Evolv are lightweight and are ideal for basic level woodworking / carpentry. Think of biscuit joints, small bookracks and beginner level tables etc.

Source:SKILSAW

The other category overlooks stationary table saws such as Bosch 4100-09; they are bigger, meaner and faster. Stationary table saws are also expensive, and sometimes they could be a little inaccurate as long as precision is concerned. These saws are used by a pure breed of professionals for the sheer cutting power, raw RPM, and cumulative time consumption factor.

Stationary saws are also called contractor table saws such as Makita 2705-10 for example. The reason is evident; if you happen to be a carpenter, you can sign up for big contracts to help make a living for yourself. Contractor table saws are designed to assist woodworking enthusiasts with bigger level projects.

Source:Dewalt

These table saws are heavy. It is not easy to move them around from one job site to another. Therefore if you are looking to buy a contractor series table saw, make sure that you have allocated a special space for it at your work site. If the nature of your work requires you to move a lot, then buy a SKILSAW table saw that comes with a factory-supplied stand with interlocking wheelbase.

For the record, there are other categories of table saws too. I only mentioned portable and stationary table saws because they are used commonly as compared to the appended categories, such as; but not limited to the following:

Cabinet Table Saws

These saws are placed higher up the food chain. I have not reviewed this category because it only caters to a very specific niche audience. These table saws have a minimum 5 Horsepower; they are heavier and meant for extreme enthusiasts who want to take up on beefier projects. Imagine at least 600 Lbs. weight sitting on a steel grade table stand – hence the expression “cabinet table saws.”

Hybrid Table Saws

Hybrid table saws are a cross cultured breed between contractor table saws and cabinet table saws. They don’t weigh as much as cabinet based products, but manufacturers still enclose them in a cabinet shaped covering.

Hybrid table saws incorporate a blend of technologies from different categories. This is intentionally done by manufacturers to give a rather unique experience to woodworkers. Hybrid table saws offer more customization and fine tuning opportunities; you can further enhance the resultant cutting capacity to achieve the desired effect.

Bear in mind that these table saws are not easy to operate. They are a little bit on the “fancier” side, and have a lot of extra control settings that might confuse you a little. This is one of the reasons as to why I never wrote any review about this specific category. Regardless, you can check out hundreds of YouTube videos where you can get a gist of what hybrids are all about.

What Are the Primary Parts In a Table Saw?

Source:SKILSAW

Of all the table saws that I have reviewed at this website, they basically have two kinds of motors. The first one is the direct drive motor category; the second one is the worm drive motor category. Direct drive motor table saws such as SKIL 3410-02 normally operate at 120V standard voltage. They have comparatively lower RPM, and are meant for general cutting purposes.

The worm drive category motors are robust. Their bearings have minimum degree of friction, hence producing more torque that helps to cut efficiently through any type of wood. Well, not “any” type, but these motors help table saw circular blades to wedge through tough wood types easily.

What Types of Accessories Should Be There With a Table Saw?

A typical home owner table saw comes with a couple of accessories that assist with assembly, cutting and other important chores. If it is your first time buying a table saw, you should keep an eye out for these accessories. Do keep in mind that it is not necessary for a manufacturer to send all the accessories listed below – or, I may have missed something. Just read through with an open mind and make a side note if necessary.

Dado Blade Set:

These blades are special, and are normally used to replace the stock blade of the table saw. Dados are usually smaller in size, but they can be very useful whenever you’re looking to create shelves, joints or such things.

Extension Cord:

Some table saws support extension cord connectivity. This helps to extend the reach of the table saw – i.e. if it is located further away from your actual work site. In such cases, you can use a long 100 Ft, high resistance, extension cable to overcome any issues or whatsoever.

Router Tables, Crosscut Sleds and Stands:

These accessories are sometimes included for free with a brand new table saw order. Some manufacturers don’t include them, but you can always create a stand if you have enough skill level under your belt. Router tables, fences and dados refine the results – they may or may not be necessary to a project’s requirements.

What Should Be The Main Safety Features in a Table Saw?

All power tools that are used for cutting – they should have ample security measures to help protect users against serious injury. In fact, OSHA mandated that table saws, circular saws and such other category tools are supposed to have a certain number/ standard of safety features to keep saw owners on the safe side.

Blade guards are important; you will notice em’ on a lot of table saws as a plastic made transparent structure that moves up and down over the blade. These guards are installed on a pivotal elbow point right behind the blade or somewhere near the blade’s general position.

Source:Bosch

Likewise, there is an elbow shaped “blade” that is installed right behind the main circular blade on a table saw. This is called the riving knife, and it’s main purpose is to prevent kickback motion, which occurs in a sudden upward direction towards the users’ face. The riving knife also helps to keep the cut material aligned in a straight shape.

Moving on, there is a magnetic switch, which permanently turns off the table saw if it goes off. Let’ say you have left a table saw unattended while it is running. In this scenario, if there’s an auto off/ standby system timer, the table saw will turn off, but at the same time, the magnetic switch system will trip and keep the table saw off until it is turned on manually. Sometimes people forget that the table saw is in standby mode, and as soon as accidental contact is made, the blade cuts right through the limb within seconds!

The biggest safety feature would be to be mindful of your surroundings when using these power tools. Wear high quality protective gear and keep your distance from the table saw blade while it is in motion. A lot of users use a prong or an extendable arm to maintain contact with the cut material, instead of using their hands to put pressure on it.

The only accessory which can make a table saw owners’ life a living hell is the spanner set. Manufacturers always include them as an essential part of the table saw product bundle, but they are not obliged to do so. Spanners make it all the more easy to screw, unscrew and adjust various parts of the table saw. If, for some reason, a spanner set is not included in your order, don’t forget to contact the concerned company rep immediately.

Different Blade Types in Table Saws:

Throughout my table saw reviews, I didn’t go into a lot of details as far as blades were concerned. I do recall talking about carbide tipped and carbide made blades vs. stainless steel blades, but that’s about it. If we explore this topic a bit further, you should know the “tooth” positioning, shape and distance matters a lot in determining the cut type.

Likewise, the tooth shapes determine the shape of straight line cuts, cross cuts, rip cuts – so on and so forth. As an expert and he will guide you better in this field. You should know that the stock blade which comes with table saws is made for general cutting purposes. It will work fine for as long as you are considering cutting for normal projects.

Source:Craftsman

Are There Any Specifics To Keep in Mind When Buying a Table Saw?

As a matter of fact, there are. For instance, you should take a recap of your requirements before blowing up a wad of your hard-earned cash. First timers usually buy table saws on impulse; they see a couple of YouTube videos, do a bit of comparison and the next thing you know is that they are at the order checkout screen.

Before narrowing down on a specific make and model of a table saw, measure its performance against the types of projects you have in mind. Compare table saw pricing and features at different online retailer websites. For instance, if you are looking up Table Saws at Amazon, then they normally list down a comparison table somewhere at the respective sales page. This will help you to check out the specs and such other features at a cursory glance.

Look for other extra perks such as safety features, extra tools n’ accessories supplied with the table saw, ease of use, ergonomics – so on and so forth. While you are at it, make sure that the table saw clearly mentions the inclusion of a dust port; unless and until you don’t mind working at a job site covered in saw dust.

A dust port is not necessary, but it can assist in keeping the work place squeaky clean throughout the tenure of the wood working project. Many table saws come with a dedicated dust collection and emission port. This is an extra feature that doesn’t directly affect the work output.

Last but not the least: always make sure that you are reading reviews from other fellow customers who made verified purchases. These reviews are more of a direct heart-to-heart rant where table saw users express their appreciation or concern over a particular product.

If everything seems right, it is time to add the item to the cart and check out before it’s too late. Oh, and don’t forget about the table saw manufacturer warranty. Some warranty policies are too damn rigid, which makes returns, refunds and replacements a pain in the ass.

Download Your 10 Home Improvement Tips And Significantly Grow The Value Of Your Home Today!

We take your privacy seriously.No spam. See our terms here